STEC-00911P-TTAu-T200-NS-AlN

Incazelo

Imibhangqwana engu-9, imojuli engu-3.6/3.0 mm × 1.6mm yosayizi eyenziwe nge-ingot ekhethiwe yokusebenza okuphezulu ukuze ifinyelelwe.

ukusebenza okupholile okuphakeme kanye ne-delta T enkulu efika ku-74 ºC, edizayinelwe ukupholisa okuphakeme nokufudumeza kufikela

200 ºC izinhlelo zokusebenza.Uma ukusebenza okuphezulu noma izinga lokushisa lokucubungula liyadingeka, sicela ucacise, singakwazi ukuklama

futhi wenze imojuli eyenziwe ngokwezifiso ngokwezidingo zakho ezikhethekile.

Izici

◼Azikho izingxenye ezihambayo, akukho msindo, nesimo esiqinile

◼Isakhiwo esihlangene, sincane ngosayizi, silula ngesisindo

◼Iyahambisana nemvelo

◼I-RoHS iyahambisana

◼Ukulawula izinga lokushisa okunembile

◼Ithembeke kakhulu ngekhwalithi, ukusebenza okuphezulu

Izinhlelo zokusebenza

◼Isiqandisi sesevisi yokudla nesiphuzo

◼I-cooler box ephathekayo yezimoto

◼Ukupholisa uketshezi

◼Izinza lokushisa

◼I-CPU epholile futhi ithuluzi lesayensi

◼Amasistimu wezithombe nezokwelapha

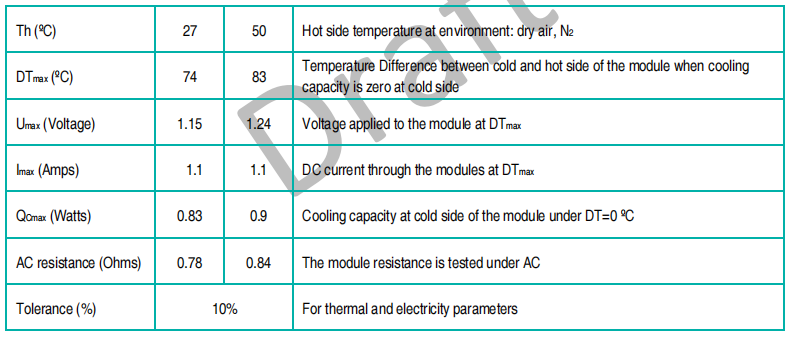

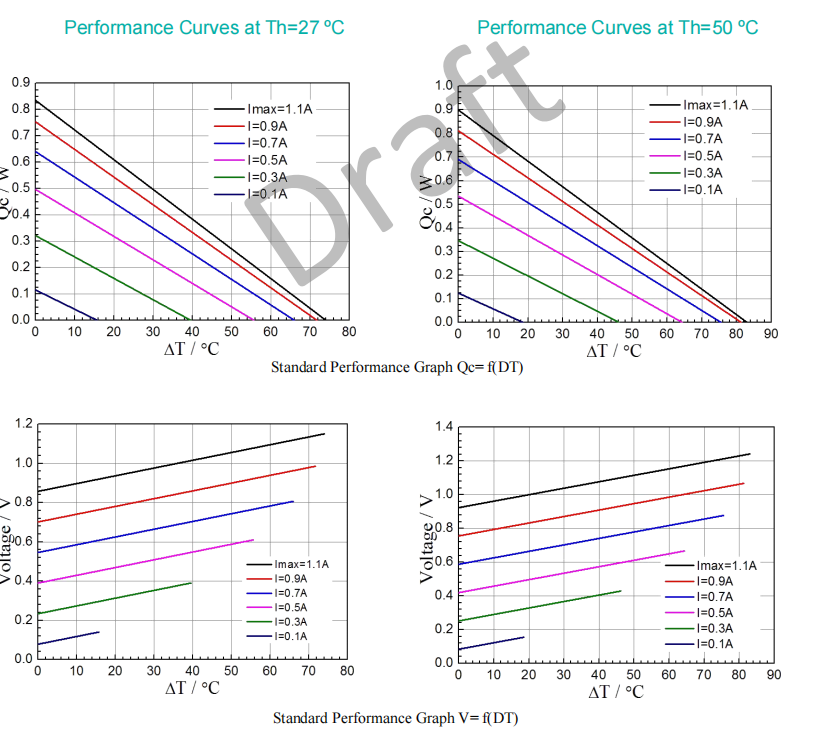

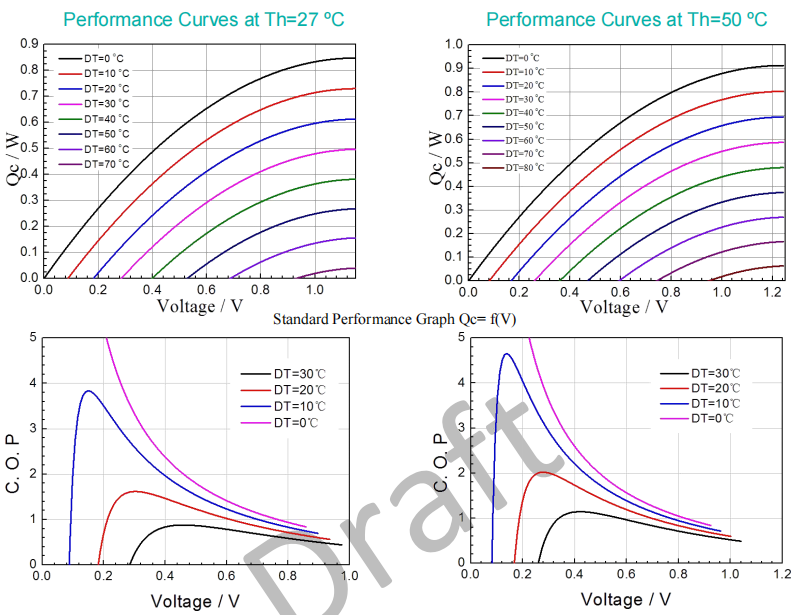

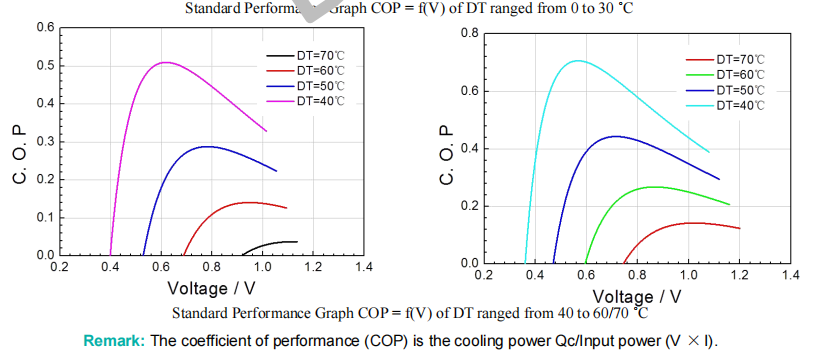

Izici zikagesi

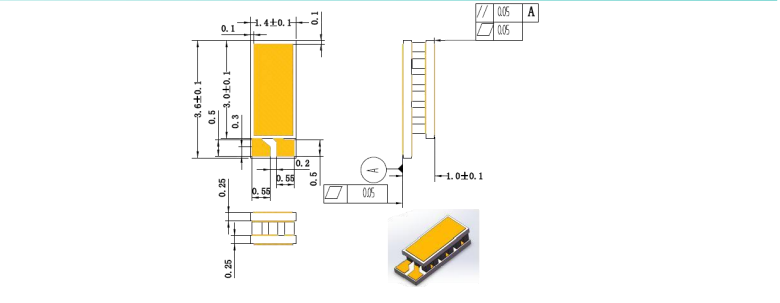

Izici Zejiyomethri

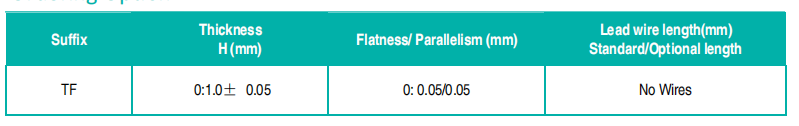

Izinketho Zokukhiqiza

A. Solder:

T200: CuSn (Tmelt=227ºC)

B. I-Sealant:

NS: Akukho ukuvalwa

C. Ceramics:

I-Aluminium Nitride (AlN)

Izinketho ze-D. Ceramics Surface:

Ihlangothi elishisayo: Insimbi (Au Plating)

Uhlangothi olubandayo: Insimbi (Au Plating)

Inketho yoku-oda

Isexwayiso sokuSebenza

◼Namathisela uhlangothi olubandayo lwemojuli entweni ezopholiswa

◼Namathisela uhlangothi olushisayo lwemojuli kurediyetha yokushisa ukuze kuqedwe ukushisa

◼Ukusebenza ngaphansi kwe-Imax noma i-Vmax

◼Sebenza ngaphansi kwe-DC

Qaphela: Yonke imininingwane ingashintsha ngaphandle kwesaziso.

Bhala umyalezo wakho lapha futhi usithumelele wona